Alternator

Alternator Specification

- Features

- Corrosion resistant, heat dissipation, robust structure

- Use

- Automotive and Industrial Power Generation

- Style

- Industrial

- Surface Finish

- Powder Coated

- Size

- Standard/OEM Size

- Assembly

- Assembled

- Power Type

- AC

- Type

- Rotating Electrical Machine

- Material

- Aluminum and High Grade Steel

- Dimensions

- Customized as per requirement

- Shape

- Round/Cylindrical

- Color

- Silver/Grey

- Function

- Converts mechanical energy to electrical energy

- Age

- New

Alternator Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Western Union, Paypal, Cheque

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Months

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Alternator

Automotive alternator

With consistent efforts to maintain the norms of the market, we are able to manufacture and supply Automotive alternator. Finest quality raw materials and components are obtained from the prime sellers of the market have been used for the manufacturing of these alternators. These products are applauded by our clients for their defect free performance and high durability. Owing to their smooth operation, these products are used for charging the battery and powering the electric while the engine is operating. Packed in special packaging material, Automotive alternator is delivered to the clients in a safe and secure way

Precision Engineering with Robust Construction

Built with high-quality aluminum and steel, this alternator delivers outstanding durability and strength. The powder-coated finish ensures enhanced corrosion resistance while maintaining an attractive appearance. The advanced fan cooling system, combined with Class H insulation, provides superior heat dissipation and operational reliability.

Versatile Application for Automotive and Industrial Needs

Engineered to accommodate both standard and custom installations, this alternator serves a wide array of applications, including tractors, trucks, industrial machinery, and generators. With bracket mounting and varied voltage options, it is the go-to solution for seamless integration into new or refurbished power systems.

FAQs of Alternator:

Q: How is this alternator installed in industrial or automotive machinery?

A: Installation of this alternator is straightforward, thanks to its bracket mount design. It comes fully assembled and can be mounted directly onto compatible engines or frames. For machinery with specific requirements, custom-sized models are available to ensure a perfect fit.Q: What benefits does the Class H insulation and fan cooling provide?

A: Class H insulation enhances the alternators heat tolerance, enabling it to perform reliably under high-load conditions. The integrated fan cooling system further improves heat dissipation and extends the overall lifespan of the alternator, resulting in consistent performance and reduced risk of overheating.Q: When should I choose a 12V output versus a 24V output alternator?

A: The voltage selection depends on your applications electrical system requirements. Heavy-duty vehicles and industrial machinery often require 24V for higher power needs, while 12V is more common in standard automotive applications and smaller equipment.Q: Where can this alternator be used effectively?

A: This alternator is versatile and well-suited for use in tractors, trucks, industrial machinery, power generators, and other equipment requiring dependable AC power conversion. Its adaptable nature makes it valuable in numerous settings, from agricultural to industrial sectors.Q: What is the process to request a customized alternator size or dimension?

A: To request a custom alternator, provide your specific dimension or OEM sizing requirements to the manufacturer. The alternator will then be produced to your specifications, ensuring proper integration with your existing systems.Q: How is noise minimized during alternator operation?

A: The alternators low-noise design is achieved through precision engineering, balanced rotating parts, and efficient fan cooling. This makes it suitable for environments where quiet operation is essential, such as in generator rooms or near sensitive electronic equipment.Q: What are the primary advantages of using this powder-coated, corrosion-resistant alternator?

A: The powder-coated surface enhances durability and resistance to environmental factors like moisture and chemicals. This, coupled with corrosion-resistant materials and robust construction, ensures long service life and minimal maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cut section Model Of Different Automobile Parts Category

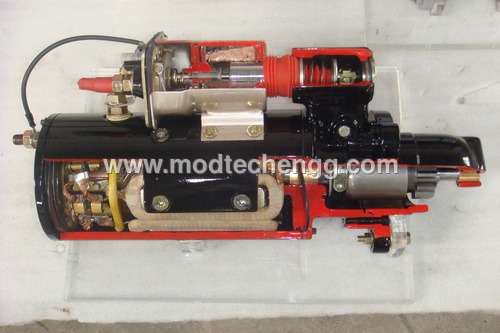

Motor Starter

Price 2000 INR

Minimum Order Quantity : 1 , , Piece

Shape : Rectangular

Color : Black & Grey

Dimensions : 130 x 75 x 100 mm

Weight : Approx. 820 g

Training Platform For Abs Brake System

Price 200000 INR

Minimum Order Quantity : 1 , , Piece

Shape : Rectangular Base with Mounted ABS System

Color : Silver, Grey, Transparent Panel Sections

Dimensions : 1500 mm x 800 mm x 1800 mm

Weight : Approx. 105 kg

Working Demo Board Of CFDI System

Price 2000 INR

Minimum Order Quantity : 1 , , Unit

Shape : Rectangular

Color : Blue/White board with colored components

Dimensions : 360mm x 260mm x 110mm

Weight : Approx. 1.2 Kg

Cut Section Model Of Centrifugal Clutch

Price 2000 INR

Minimum Order Quantity : 1 Piece

Shape : Rectangular Base with Cylindrical Clutch Assembly

Color : Multicolor (Red, Blue, Silver, Black)

Dimensions : Approx. 30cm x 18cm x 18cm

Weight : 3.5 kg approx.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS