MIG WELDING

MIG WELDING Specification

- Model No

- MIGW-001

- Features

- Continuous wire feeding, adjustable current, stable arc, efficient cooling system

- Surface Finish

- Polished and anti-corrosive coating

- Style

- Handheld, torch-operated

- Weight

- Lightweight for easy handling

- Assembly

- Easy to assemble with standard connection interfaces

- Use

- Metal inert gas welding applications

- Power Type

- Electric (AC/DC)

- Size

- Fits standard welding setups

- Type

- Semi-automatic arc welding equipment

- Material

- Stainless steel and alloy components

- Dimensions

- Standard sizes as per industrial welding requirements

- Shape

- Ergonomic torch design

- Color

- Metallic finish with insulated grip

- Function

- Fuses metal pieces using consumable wire and shielding gas

- Age

- Suitable for professional and industrial use; not recommended for children

- Advantage

- High welding speed, minimal slag, strong welds

- Wire Diameter Range

- 0.8 mm to 1.2 mm

- Applications

- Automotive, fabrication, machinery, repairs

- Welding Thickness Capacity

- Up to 10 mm

- Duty Cycle

- 60% at maximum rated output

- Cooling Method

- Air-cooled

- Input Voltage

- 220V 415V

- Safety Standard

- Integrated overheat protection

- Trigger Type

- 2-step trigger mechanism

- Shielding Gas Compatible

- Argon, CO2, Argon/CO2 Mix

- Portability

- Portable with carry handles

MIG WELDING Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Western Union, Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, Australia

- Main Domestic Market

- All India

About MIG WELDING

Model No. MT-Z27

| MIG WELDING |

|

| |

| Input voltage : 3 Phase 400V |

|

| |

| Welding current range: 20 - 220 Amps |

| ||

| Weldable wires: | Steel wire: 0.6 - 1 mm | ||

|

|

| Stainles Steel Wire: 0.8 - 1 mm | |

|

|

| Aluminium Mg-Si Wire: 0.8 - 1 mm | |

Precision Welding Performance

MIGW-001 delivers high welding speed and strong, clean welds with minimal slag. Its ergonomic torch and continuous wire feeding support stable arc performance. Adjustable current and efficient air cooling make it ideal for professional metal inert gas applications requiring reliability and accuracy in industrial and automotive settings.

Versatile Shielding and Portability

This welding equipment is compatible with Argon, CO2, and their mix, suiting various welding processes. Lightweight construction, standard dimensions, and carry handles provide convenient portability for onsite repairs or workshop use. The easy assembly and standard interfaces support quick setup in diverse work environments.

FAQs of MIG WELDING:

Q: How does the MIGW-001 ensure operator safety during welding operations?

A: The MIGW-001 features integrated overheat protection and an insulated ergonomic grip, reducing risk during prolonged welding. Its air-cooled system maintains safe operating temperatures, and the torchs design helps prevent accidental burns or electrical contact, supporting compliance with industrial safety standards.Q: What is the recommended shielding gas for optimal weld quality?

A: You can use Argon, CO2, or an Argon/CO2 mix with this machine. The choice depends on your material and desired weld characteristics; Argon typically yields smooth, high-quality welds, while CO2 offers deeper penetration. A mix balances spatter and penetration for versatile applications.Q: When should I adjust the wire diameter within the 0.8 mm to 1.2 mm range?

A: Select wire diameter based on the thickness of your workpiece and required weld strength. Thinner wires (0.8 mm) suit lighter fabrication, while thicker wires (up to 1.2 mm) are ideal for welding up to 10 mm materials, such as automotive frames or machinery components.Q: Where is the MIGW-001 most commonly used?

A: This equipment is widely employed in automotive workshops, metal fabrication plants, machinery maintenance, and industrial repair environments across India. Its portable design and handle make it convenient for onsite and workshop-based tasks.Q: What is the process for assembling and setting up this MIG welding machine?

A: Assembly is straightforward, using standard connection interfaces for quick installation. Connect the torch, power, and wire feeder, select your shielding gas, and adjust current as needed. The ergonomic design and integrated carry handles ensure hassle-free transport and setup in any standard welding station.Q: What benefits does the MIGW-001 provide over traditional welding methods?

A: It offers high welding speeds, minimal slag formation, and strong, consistent welds. The continuous wire feed and stable arc reduce downtime and deliver efficient results, making it highly advantageous for industrial applications requiring productivity and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tool And Equipments Category

COMMON RAIL FLOW METER

Price 2000 INR

Minimum Order Quantity : 1 Unit

Dimensions : 30 cm x 20 cm x 12 cm

Age : Brand new

Weight : Approximately 1.7 kg

Assembly : Comes fully assembled and ready to use

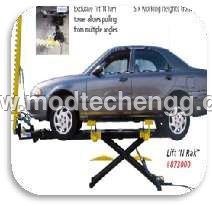

CAR CRASH EQUIPMENT CHASSISLINER - LIFT N RAK

Price 200000 INR

Minimum Order Quantity : 1 Unit

Dimensions : 3988 mm (Length) x 1045 mm (Width) x 2970 mm (Height)

Age : All agestool for professional use

Weight : Approx. 1200 kg

Assembly : Partial assembly required

PLASMA CUTTER

Price 20000 INR

Minimum Order Quantity : 1 Unit

Dimensions : 550 x 230 x 350 mm

Age : Adult

Weight : 20 kg

Assembly : Ready to Use

PAINTBOOTH

Price 2000 INR

Minimum Order Quantity : 1 , , Unit

Dimensions : 5800 mm x 4000 mm x 3150 mm (L x W x H)

Age : New

Weight : Approx 1200 kg

Assembly : PreFabricated Modular Assembly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS