MODEL OF CUT SECTIONED MULTI PLATE CLUTCH SYSTEM

MODEL OF CUT SECTIONED MULTI PLATE CLUTCH SYSTEM Specification

- Stand Type

- Metallic Stand with Base

- Shaping Mode

- Cut Sectioned Model

- Material

- High-grade Acrylic and Metal Components

- Product Type

- Educational Training Model

- Mould For

- Clutch System Demonstration

- Mould Size

- Standard Lab Size (Approx. 350 mm x 250 mm x 150 mm)

- Mould Material

- Transparent Acrylic and Alloy Steel

- Design

- Detailed Multi-Plate Clutch Construction

- Quality

- Precision Engineered Educational Quality

- Demonstration Features

- Shows multiple friction and pressure plates, release mechanism, and input/output motion

- Operation Method

- Manual Hand Rotation

- Color

- Silver (Metal) with Transparent Top Sections

- Weight

- Approx. 5 kg

- Visualization

- Cut section reveals pad placement and working principle

- Educational Use

- Practical Demonstration of Clutch Engagement and Disengagement

- Durability

- Long Service Life for Classroom Handling

- System Representation

- Multi Plate Clutch (Cut sectioned for internal visibility)

- Safety

- All Edges Smoothened for Safe Handling

- Finish

- Smooth, Rust-resistant

- Application

- Automobile Engineering and Technical Education

- Mounting

- Fixed on Stable Base for Tabletop Use

- Scale

- Reduced/Proportional to Real Mechanism

MODEL OF CUT SECTIONED MULTI PLATE CLUTCH SYSTEM Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Paypal, Western Union, Cheque

- Supply Ability

- 100 Units, , Per Week

- Delivery Time

- 1 Months

- Main Export Market(s)

- Middle East, South America, Western Europe, Africa, Central America, Asia, North America, Australia

- Main Domestic Market

- All India

About MODEL OF CUT SECTIONED MULTI PLATE CLUTCH SYSTEM

Model No. MT-I04

MODEL OF CUT SECTIONED MULTI PLATE CLUTCH SYSTEM :

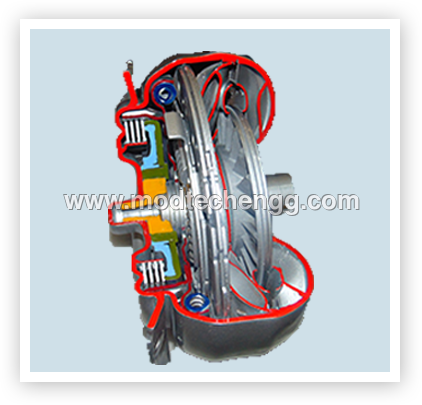

This model is made out of full size original multi plate clutch which is suitably sectioned to show the multi plate friction plate arrangement and its working principle.

The model will be mounted on wooden base, Suitable color imported painting will be carried out along with Miracle coating for the model will be done for extra gloss and shine. The painting will be carried out in such a way that different colors will be use for different components such as identification of sectioned area etc according to the colors code for easy identification of different systems and mechanisms. All the hardwares and gears will be suitably electroplated

In-Depth Mechanical Visualization

This cut-sectioned model allows users to observe the precise placement and function of friction and pressure plates within a multi-plate clutch. The transparent acrylic top and alloy steel construction provide true-to-life internal visualization, enabling learners to grasp how engagement and disengagement work in real automotive systems.

Hands-On Learning Experience

Designed for manual hand rotation, the model encourages interactive learning. Students and instructors can actively demonstrate and observe the clutchs operation, including the release mechanism and the resulting motion transfer between input and output, all within a stable and safe environment.

Built for Educational Excellence

With smooth, rust-resistant finishes and carefully engineered edges for safe handling, this model is made for repeated classroom use. Its precise scale, robust quality, and easy tabletop placement make it an ideal choice for technical education settings in India and beyond.

FAQs of MODEL OF CUT SECTIONED MULTI PLATE CLUTCH SYSTEM:

Q: How does the cut-sectioned multi plate clutch model demonstrate clutch engagement and disengagement?

A: The model features a transparent section revealing the multiple friction and pressure plates. By manually rotating the input shaft, users can see and understand how the plates engage and disengage to transfer motion, effectively simulating real-world clutch operation.Q: What educational benefits does this clutch model provide for students?

A: This model enhances practical understanding by visually demonstrating the internal workings of a multi-plate clutch. It aids technical students in comprehending the fundamental concepts of automotive transmission systems, bridging the gap between theoretical learning and real-world mechanism.Q: When is this demonstration model typically used in technical education?

A: The model is primarily used during laboratory sessions, classroom teaching, or technical demonstrations, whenever there is a need to practically illustrate the principles of clutch operations in automotive engineering courses.Q: Where can this clutch system model be utilized effectively?

A: It is ideal for use in engineering colleges, technical training institutes, and automotive workshops that focus on vocational training. Its tabletop design allows for stable placement in classrooms or laboratories.Q: What materials are used in constructing the model and are they durable?

A: High-grade transparent acrylic and alloy steel are used to manufacture the model, ensuring durability and longevity. The smooth, rust-resistant finish and robust materials allow it to withstand regular classroom handling.Q: How is safety ensured while handling the model during demonstrations?

A: All edges are carefully smoothened to prevent accidental cuts or injuries. The models stable metallic base ensures it remains secure during hands-on use, making it safe for students and instructors alike.Q: What are the main benefits of choosing this reduced-scale, proportionate model for learning?

A: This model offers realistic proportions and detailed construction, providing clear and accurate demonstrations in a manageable size. Its educational quality helps students gain practical insights without the logistical challenges of handling full-sized machinery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cut Section Model of Clutches Category

CUT SECTION MODEL OF SINGLE PLATE COIL SPRING CLUTCH

Price 20000 INR

Minimum Order Quantity : 1 Unit

Material : Other, Durable Engineering Plastic & Metal Components

Mould Material : Transparent Plastic and Metal

Product Type : Educational Model

Shaping Mode : Other, Cut Section Model

CUT SECTION MODEL OF DIAPHRAM CLUTCH SYSTEM

Price 20000 INR

Minimum Order Quantity : 1 , , Piece

Material : Other, Aluminum Alloy and Acrylic Components

Mould Material : High Strength, Transparent Acrylic and Metal

Product Type : Diaphragm Clutch System Demonstrator Model

Shaping Mode : Other, Educational Cut Section Model

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS