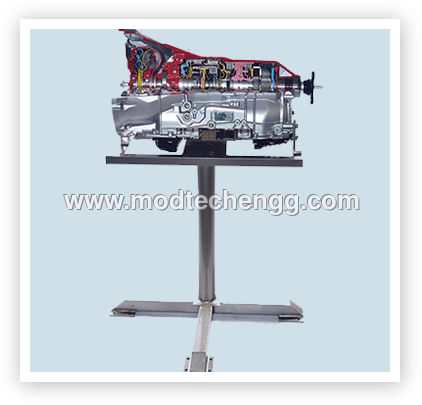

CUT SECTION MODEL OF SLIDING MESH GEAR BOX

CUT SECTION MODEL OF SLIDING MESH GEAR BOX Specification

- Use

- Demonstration and study of sliding mesh gear box mechanism

- Size

- Standard Laboratory Model Size

- Power Type

- Manual operation (hand crank or lever)

- Type

- Cut Section Working Model

- Material

- Metal with acrylic/plastic window/ABS base

- Dimensions

- 450 mm x 300 mm x 220 mm (approx.)

- Shape

- Rectangular with projections (mimics actual gearbox geometry)

- Function

- Shows sliding mesh gearbox operation including gear engagement/disengagement

- Age

- For technical students, trainees, and engineering studies

CUT SECTION MODEL OF SLIDING MESH GEAR BOX Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Paypal, Western Union, Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About CUT SECTION MODEL OF SLIDING MESH GEAR BOX

Established in the year 1989, we are becoming as one of the trusted manufacturers of Diaphragm Clutch Model. It is required to show the mechanism of working of clutch in automobiles. This model depicts the need of diaphragm which acts as clamping spring and release finger. It uses single dish diaphragm to apply clamping thrust. Offered Diaphragm Clutch Model works by applying pressure on the pressure plate in order to engage the clutch, and when the center portion of spring is pressed by the clutch pedal rim moves backward resulting in clutch disengaging.

Features:

-

Clearly shows how clutch plate remains between the flywheel & pressure plate

-

Easy to understand

-

Supreme quality

Cut Section Model Of Drophram Clutch..........................................

Clear Demonstration of Gear Mechanisms

Experience hands-on learning with our cut section sliding mesh gear box model, which offers clear visibility into constant mesh gears, sliding gears, reverse idler, and lay shaft arrangements. With a transparent window, users can observe the engagement and disengagement of gears for different drive scenarios, making demonstrations comprehensive and intuitive for technical students and engineering trainees.

Durable and Low-Maintenance Construction

Constructed from high-quality metals with a corrosion-resistant finish and mounted on a sturdy ABS base, this model withstands frequent classroom or lab use. Its robust build ensures longevity, while upkeep is limited to basic cleaning, making it an economical and reliable addition to any technical training environment.

FAQs of CUT SECTION MODEL OF SLIDING MESH GEAR BOX:

Q: How does the cut section model demonstrate gear shifting and transmission?

A: The model uses a hand-operated crank or lever to manually shift gears, allowing users to engage and disengage forward, reverse, and neutral positions. The transparent section lets users observe internal gear movements and understand the sliding mesh gearbox principle.Q: What are the primary uses of this sliding mesh gear box model?

A: This model is designed for hands-on demonstration and study in technical classrooms and laboratories. It helps students visualize the operation, gear arrangements, and shifting process in sliding mesh gearboxes, enhancing their understanding of vehicular transmission systems.Q: When should this model be used in technical education?

A: The sliding mesh gearbox model is ideal for use during introductory and advanced sessions on automotive transmissions. It is most effective when teaching concepts of gear engagement, gear ratios, and the mechanical principles behind gearboxes.Q: Where can this model be deployed for maximum educational value?

A: This model is best utilized in engineering colleges, technical training institutes, and vocational schools for in-class demonstrations, hands-on workshops, and laboratory training sessions.Q: What is the maintenance process for this gearbox model?

A: Maintenance is simple, requiring only routine cleaning to keep the transparent viewing section clear and gears free from dust or debris. The corrosion-resistant metal construction ensures long-lasting durability with minimal care.Q: What are the benefits of using a cut section sliding mesh gear box model?

A: The model provides practical insight into gear engagement and shifting, making abstract mechanical concepts tangible. It enhances student understanding, encourages active participation, and supports effective troubleshooting and analysis during technical training.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cut section Model Of Gear Box Category

CUT SECTION MODEL OF SLIDING MESH GEAR BOX

Price 200000 INR

Minimum Order Quantity : 1 Unit

Material : Highgrade metal with acrylic cut section covers

Dimensions : Approx. 350 mm x 180 mm x 180 mm (L x W x H)

Weight : Approx. 5.5 kg

Age : Suitable for technical students (16+ years)

CUT SECTION MODEL OF SYNCHROMESH GEAR BOX

Price 2000 INR

Minimum Order Quantity : 1 , , Piece

Material : Mild Steel with Acrylic Cover

Dimensions : Approx. 350 mm x 180 mm x 140 mm

Weight : Approx. 7.5 kg

Age : For Technical Students and Trainers

CUT SECTION MODEL OF GEAR BOX WITH DIFFERENTIAL

Price 20000 INR

Minimum Order Quantity : 1 , , Piece

Material : Cast Iron, Mild Steel, and Plastic Components

Dimensions : Approx. 40 cm x 30 cm x 25 cm

Weight : Approx. 1012 kg

Age : For Engineering Students and Technical Training

CUT SECTION MODEL OF FIVE SPEED MANUAL TRANSMISSIO

Price 200000 INR

Minimum Order Quantity : 1 Unit

Material : Metal, Acrylic, Painted Components

Dimensions : Approx. 55 cm x 30 cm x 35 cm

Weight : Approximately 18 kg

Age : Suitable for technical institutes and engineering students

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS