CUT SECTION MODEL OF 1 SIDE MACPHERSON SUSPENSION

CUT SECTION MODEL OF 1 SIDE MACPHERSON SUSPENSION Specification

- Stand Type

- Rigid Metal Stand with Base

- Shaping Mode

- Cut Section Model

- Material

- Metal and Acrylic Components

- Product Type

- Educational Mechanical Model

- Mould For

- Automotive Suspension Demonstration

- Mould Size

- Standard Demonstration Size (Approx. 50 cm x 20 cm x 18 cm)

- Mould Material

- Mild Steel, Acrylic and High Tensile Plastic

- Design

- Cut Section of 1 Side MacPherson Suspension

- Quality

- High Quality, Precise Finish

CUT SECTION MODEL OF 1 SIDE MACPHERSON SUSPENSION Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Western Union, Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Western Europe, Africa, Central America, Asia

- Main Domestic Market

- All India

About CUT SECTION MODEL OF 1 SIDE MACPHERSON SUSPENSION

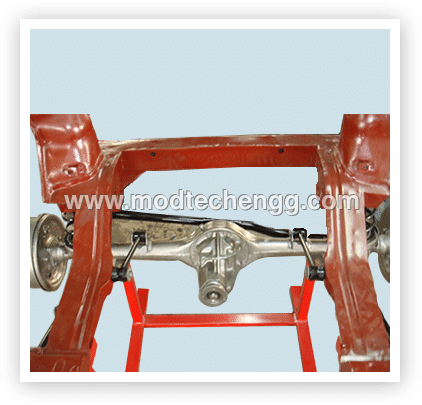

CUT SECTION MODEL OF COMPELETE ONE SIDE MACPHERSON SUSPENSION STRUT WITH DRIVE SHAFT, DISK BRAKE.

This model is made out of original used parts, will be suitably sectioned And Arranged to demonstrate the internal construction details showing the minute information With Suspension Strut with spring and shock absorber, disc brake, calliper, wishbone drive shaft etc., and working of the same can be shown, the model will be suitably painted and The entire model is mounted on a sturdy iron frame.

Product Range

| Model No. | Description |

|---|---|

| MT-N01 | CUT SECTION MODEL OF COMPLETE ONE SIDE MACPHERSON SUSPENSION STRUT WITH DRIVE SHAFT, DISK BRAKE |

| MT-N02 | CUT SECTION MODEL OF COMPLETE BOTH SIDE MACPHERSON SUSPENSION STRUT WITH DRIVE SHAFT, DISK BRAKE |

| MT-N03 | CUT SECTION MODEL OF COMPLETE FRONT SUSPENSION WITH LONGITUDINAL TORSION BAR |

| MT-N04 | CUT SECTION MODEL OF COMPLETE COIL SPRING TYPE FRONT SUSPENSION SYSTEM |

| MT-N05 | CUT SECTION MODEL OF COMPLETE BOTH SIDE WITH DOUBLE WISHBONE SUSPENSION WITH DRIVE SHAFT |

| MT-N06 | CUT SECTION MODEL OF COMPLETE LEAF SPRING SUSPENSION SYSTEM WITH REAR AXLE |

| MT-N07 | CUT SECTION MODEL OF COMPLETE COIL SPRING TYPE REAR SUSPENSION SYSTEM |

| MT-N08 | CUT SECTION MODEL OF COMPLETE AIR SUSPENSION SYSTEM |

Comprehensive Educational Demonstration

This cut section model is specifically designed for educational environments such as technical institutes, automotive labs, and workshops. By presenting a detailed sectional layout of a one-side MacPherson suspension, it enables students and professionals to study and understand the principles of suspension, wheel alignment, and steering movements in a real-world context.

Quality Construction and Lasting Durability

Manufactured using high-quality mild steel, acrylic, and high-tensile plastic, this model blends accuracy with endurance. Its anti-corrosive paint and color-coded components ensure both clarity and resilience, while fixed mounting on a rigid metal base further adds to its longevity and operational stability.

Enhanced Visibility and Ease of Use

The inclusion of clear acrylic windows and color segmentation allows users to observe internal mechanics easily, making the educational process both insightful and engaging. Movable parts showcase the function and interplay between components, providing practical demonstration opportunities.

FAQs of CUT SECTION MODEL OF 1 SIDE MACPHERSON SUSPENSION:

Q: How does the cut section model demonstrate MacPherson suspension principles?

A: The model features a true-to-scale sectional representation of a single-wheel MacPherson suspension. Movable parts such as the spring, damper, and control arm accurately simulate suspension movement, enabling users to visualize and understand how these components interact to absorb shocks and maintain wheel alignment.Q: What makes this model suitable for technical institutes and automotive labs?

A: Its precise construction, realistic arrangement, and clear visibility make it a valuable teaching aid for institutions. The robust, color-coded components and stable mounting allow repeated usage for hands-on demonstrations, making it ideal for instructional purposes.Q: When should this model be used in an educational setting?

A: It is best used during practical sessions on automotive suspension systems, wheel alignment theory, and steering mechanism demonstrations. Instructors can utilize it to reinforce lectures with tangible, real-time visualization of mechanical principles.Q: Where can the cut section model be placed for demonstration?

A: Designed with a rigid metal base, the model can be securely placed on lab benches, classroom tables, or demonstration platforms, ensuring stability during use in any learning environment.Q: What benefits does the color-coded and acrylic window design provide?

A: Color-coding helps distinguish suspension components for easier identification, while the clear acrylic windows offer unobstructed views of internal mechanisms, enhancing learning by allowing observation of component movement and interaction.Q: How is the model maintained for long-term use?

A: Minimal maintenance is required, thanks to the anti-corrosive coatings and high-quality materials. Occasional cleaning of acrylic surfaces and checking for secure fittings will keep the model in optimal condition for years of instructional use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cut Section Model Of Suspension System Category

CUT SECTION MODEL BOTH SIDE MACPHERSON SUSPENSION

Price 2000 INR

Minimum Order Quantity : 1 Piece

Product Type : Educational Training Model

Material : Other, Mild Steel, Cast Iron, Rubber, Acrylic

Mould For : MacPherson Suspension System (Both Sides)

Mould Material : Steel & Acrylic

CUT SECTION MODEL OF COMPLETE WISHBONE SUSPENSION

Price 20000 INR

Minimum Order Quantity : 1 Piece

Product Type : Automotive Training Model

Material : Other, Metal and highgrade plastic

Mould For : Wishbone Suspension System

Mould Material : Mild Steel/Engineering Plastic

CUT SECTION MODEL OF COIL SPRING REAR SUSPENSION

Price 200000 INR

Minimum Order Quantity : 1 Unit

Product Type : Rear Suspension Educational Model

Material : Other, Metal and HighGrade Plastic

Mould For : Automotive Training and Demonstration

Mould Material : Mild Steel and Transparent Acrylic

CUT SECTION MODEL OF COMPLETE FRONT SUSPENSION

Price 20000 INR

Minimum Order Quantity : 1 , , Unit

Product Type : Educational Training Model

Material : Other, HighGrade Metal and Acrylic Components

Mould For : Automotive Front Suspension Demonstration

Mould Material : Metal, Acrylic Windows

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free