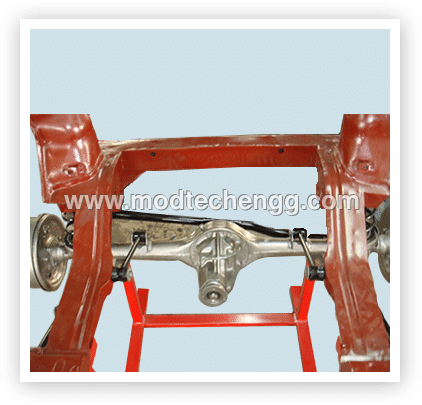

CUT SECTION MODEL OF COMPLETE FRONT SUSPENSION

CUT SECTION MODEL OF COMPLETE FRONT SUSPENSION Specification

- Stand Type

- Sturdy Powder-Coated Metal Base with Mounts

- Shaping Mode

- Cut Section Model

- Material

- High-Grade Metal and Acrylic Components

- Product Type

- Educational Training Model

- Mould For

- Automotive Front Suspension Demonstration

- Mould Size

- Full Scale (as per actual vehicle) or Customized

- Mould Material

- Metal, Acrylic Windows

- Design

- Sectional, Exposing Internal Components

- Quality

- Laboratory and Industrial Training Standard

- Mounting

- Fixed securely to base for 360-degree observation

- Application

- Automobile Engineering Education, Technical Training Institutes, Polytechnic Labs

- Durability

- Long-lasting with corrosion-resistant finish

- Demonstrates

- Complete Front Suspension Assembly (coil spring, shock absorber, control arm, steering knuckle, etc.)

- Dimensions

- Approx. 90 x 60 x 50 cm (customizable as per client requirements)

- Operating Instruction Manual

- Included with step-by-step assembly and use guidance

- Display Features

- Movable and fixed section parts to show mechanism

- Finish

- Smooth, easy-to-clean surface

- Model Number

- FS-CSM-Complete

- Weight

- Approx. 18-25 kg (varies depending on configuration)

- Cut Sections

- All major components sectioned for clear viewing of working parts

- Paint

- Components painted in contrast colors for identification

CUT SECTION MODEL OF COMPLETE FRONT SUSPENSION Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Western Union, Paypal, Cheque

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 1 Years

- Main Domestic Market

- All India

About CUT SECTION MODEL OF COMPLETE FRONT SUSPENSION

CUT SECTION MODEL OF COMPELETE FRONT SUSPENSION WITH LONGITUDINAL TORSION BAR..

This model is made out of original used parts, will be suitably sectioned And Arranged to demonstrate the internal construction details showing the minute information With Suspension System with longitudinal torsion bar arrangement, shock absorber, etc., and working of the same can be shown, the model will be suitably painted and The entire model is mounted on a sturdy iron frame

Engineered for Educational Excellence

This model brings the classroom lesson to life by providing a tactile, interactive demonstration of a complete automotive front suspension assembly. Its full-scale or customizable size allows students to observe and understand the intricacies of suspension mechanisms in a way that theoretical diagrams cant match. Paint in contrasting colors helps learners clearly recognize individual components.

Durable, High-Quality Construction

Constructed with a combination of high-grade metals and acrylic window sections, the model is designed to endure regular hands-on use in busy lab environments. Its corrosion-resistant finish and smooth surfaces make it both long-lasting and simple to clean, ensuring years of reliable service for repeated demonstrations.

Easy to Use and Maintain

A comprehensive operating manual accompanies the model, making assembly and demonstration straightforward for instructors and students alike. The sturdy stand and base keep the model secure during close examination and movement of both fixed and moving parts, enabling safe, 360-degree access while highlighting the functional interplay of the suspension system.

FAQs of CUT SECTION MODEL OF COMPLETE FRONT SUSPENSION:

Q: How does the CUT SECTION MODEL OF COMPLETE FRONT SUSPENSION aid in automotive engineering education?

A: This model allows students and trainees to visually and physically explore the structure and function of a vehicles front suspension. By exposing and painting each component in contrasting colors, it simplifies the identification of parts, enhancing conceptual clarity and fostering deeper understanding during technical training sessions.Q: What components are included and sectioned in this demonstration model?

A: The model displays a full front suspension assembly, meaning key elements such as the coil spring, shock absorber, control arm, and steering knuckle are all present and sectioned. Movable and fixed sections are featured to demonstrate actual working mechanisms and internal constructions.Q: When and where should this model be used for optimal educational value?

A: This cut section model is ideally used during hands-on sessions in technical institutes, polytechnic labs, and engineering workshops. It can be incorporated into demonstrations, practical assessments, or interactive lessons whenever a visual and tactile understanding of automotive suspension systems is required.Q: What is the process for assembling and operating the model?

A: Each unit comes with a detailed operating instruction manual that guides users through step-by-step assembly and demonstration procedures. The model is supplied mounted on a sturdy base to allow secure handling, and both fixed and movable parts are designed for straightforward manipulation and inspection.Q: Where is the CUT SECTION MODEL OF COMPLETE FRONT SUSPENSION manufactured?

A: This model is manufactured in India, meeting laboratory and industrial training standards to ensure a quality product suitable for technical education environments.Q: How does the contrasting paint improve the educational experience?

A: The use of contrasting paint on individual components allows users to quickly distinguish between different parts, streamlining identification and comprehension during demonstrations or examinations.Q: What are the maintenance requirements for this training model?

A: Maintenance is minimal, thanks to the models corrosion-resistant finish and smooth, easy-to-clean surfaces. Regular wiping and occasional inspection for loose mounting bolts are typically sufficient to keep the unit in optimal working condition.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cut Section Model Of Suspension System Category

CUT SECTION MODEL OF 1 SIDE MACPHERSON SUSPENSION

Price 2000 INR

Minimum Order Quantity : 1 Piece

Design : Cut Section of 1 Side MacPherson Suspension

Product Type : Educational Mechanical Model

Mould Material : Mild Steel, Acrylic and High Tensile Plastic

Quality : High Quality, Precise Finish

CUT SECTION MODEL BOTH SIDE MACPHERSON SUSPENSION

Price 2000 INR

Minimum Order Quantity : 1 Piece

Design : Transparent Cut Section Model

Product Type : Educational Training Model

Mould Material : Steel & Acrylic

Quality : Demonstration Grade

CUT SECTION MODEL OF COMPLETE WISHBONE SUSPENSION

Price 20000 INR

Minimum Order Quantity : 1 Piece

Design : Industrial Educational Cutaway

Product Type : Automotive Training Model

Mould Material : Mild Steel/Engineering Plastic

Quality : Educational Laboratory Grade

CUT SECTION MODEL OF COIL SPRING REAR SUSPENSION

Price 200000 INR

Minimum Order Quantity : 1 Unit

Design : Detailed Sectional View

Product Type : Rear Suspension Educational Model

Mould Material : Mild Steel and Transparent Acrylic

Quality : Laboratory Grade

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS