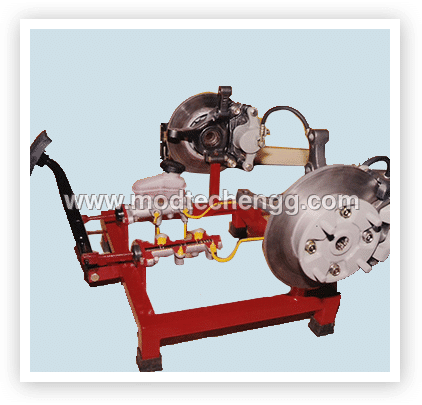

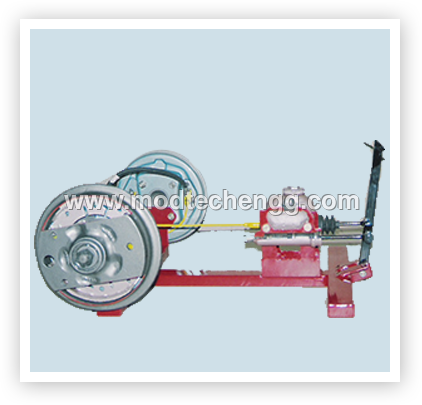

CUT SECTION MODEL OF DISC BRAKE SYSTEM TWO WHELER

CUT SECTION MODEL OF DISC BRAKE SYSTEM TWO WHELER Specification

- Stand Type

- Mounted on Acrylic/Metal Stand

- Shaping Mode

- Cut Section

- Material

- Acrylic, Metal Components

- Product Type

- Educational Training Model

- Mould For

- Disc Brake System (Two Wheeler)

- Mould Size

- Standard (Approx. 300x200x120 mm)

- Mould Material

- Acrylic Base with Metal

- Design

- Cut Section View with Detailed Internal Parts

- Quality

- Laboratory/Institutional Grade

CUT SECTION MODEL OF DISC BRAKE SYSTEM TWO WHELER Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Western Union, Paypal, Cheque

- Supply Ability

- 100 Units, , Per Week

- Delivery Time

- 1 Months

- Main Export Market(s)

- Central America, Eastern Europe, Middle East, Western Europe, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About CUT SECTION MODEL OF DISC BRAKE SYSTEM TWO WHELER

Model No. MT-K08

CUT SECTION MODEL OF DISC BRAKE SYSTEM TWO WHELER.

This model is made out of original used parts, will be suitably sectioned And Arranged to demonstrate the internal construction details showing the minute information such as the disc brake assembly, master cylinder on the handle, its piping, front wheel assembly with disc , handle bar with cylinder and brake lever etc., and working of the same can be show by operating the brake lever, the model will be suitably painted and The entire model is mounted on a sturdy iron frame.

Exceptional Educational Utility

Perfect for classrooms and laboratories, this disc brake cut section model simplifies complex automotive engineering concepts. Students can observe the entire mechanism, aiding their understanding through visual and hands-on interaction. Its detailed build and clear color coding make learning straightforward for both beginners and advanced trainees.

Precision Engineering with Durable Materials

Constructed from a combination of quality acrylic and robust metal, this model is made to withstand frequent handling and classroom use. Its impact-resistant materials and corrosion resistance ensure a long service life, while the polished finish enhances its appearance and maintenance ease.

FAQs of CUT SECTION MODEL OF DISC BRAKE SYSTEM TWO WHELER:

Q: How does the manual demonstration of the disc brake system model work?

A: The manual demonstration allows users to operate and observe internal disc brake components, such as the master cylinder, caliper, pads, rotor, pistons, and lines. By manually simulating brake activation, the movement of each part can be clearly seen, helping users understand the functioning principles of a two-wheeler disc brake.Q: What are the main benefits of using this cut section model in technical education?

A: This model offers hands-on learning, helping students visualize the working principles of disc brakes. The detailed, color-coded internal components promote clear understanding, while the robust and easy-to-clean design ensures longevity and low maintenance in busy education settings.Q: When and where can this disc brake cut section model be used effectively?

A: The model is ideal for use during classroom instruction, laboratory demonstrations, workshops, and practical exams in engineering colleges, polytechnic institutes, and vocational training centers. Its stable base and suitable size allow for convenient placement on desks or benches.Q: What process should be followed for cleaning and maintaining the model?

A: Cleaning is straightforwardsimply wipe the acrylic and metal surfaces with a soft, damp cloth to remove dust and fingerprints. The corrosion-resistant materials require minimal maintenance, ensuring the model stays clean and operational for frequent instructional use.Q: Where are the detailed moving parts located for observation?

A: All critical components, including the master cylinder, caliper, pads, rotor, pistons, and lines, are displayed through the cut-section design. This arrangement provides clear visibility of each moving part, ensuring that students can easily observe how force is transferred during brake operation.Q: How does the stable base contribute to model usage during demonstrations?

A: The sturdy acrylic/metal base prevents the model from shifting during demonstrations, allowing educators and students to interact with the display confidently. Its well-balanced design ensures safety and ease of use on various surfaces such as desks and benches.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cut Section Model of Brake System Category

CUT SECTION MODEL OF MECHANICAL BRAKE SYSTEM

Price 20000 INR

Minimum Order Quantity : 1 , , Piece

Mould Size : Standard Classroom Size

Quality : Premium Laboratory Quality

Mould For : Educational Display

Product Type : Mechanical Brake System Model

CUT SECTION MODEL OF HYDRAULIC BRAKE

Price 20000 INR

Minimum Order Quantity : 1 Unit

Mould Size : Approx. 30 cm x 20 cm x 20 cm

Quality : Laboratory/Teaching Standard

Mould For : Automotive Training / Demonstration

Product Type : Hydraulic Brake Model

MODEL OF AIR BRAKE SYSTEM WORKING

Price 200000 INR

Minimum Order Quantity : 1 , , Unit

Mould Size : Approx. 60 cm x 30 cm x 25 cm

Quality : Laboratory/Instructional Grade

Mould For : Air Brake System Working

Product Type : Demonstration Model

CUT SECTION MODEL OF DISC BRAKE SYSTEM

Price 200000 INR

Minimum Order Quantity : 1 Unit

Mould Size : Approx. 350mm x 200mm x 120mm

Quality : Laboratory Standard

Mould For : Disc Brake System

Product Type : Educational Demonstration Model

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS