MODEL OF AIR BRAKE SYSTEM WORKING

MODEL OF AIR BRAKE SYSTEM WORKING Specification

- Stand Type

- Rigid metallic frame with base support

- Shaping Mode

- Mechanical Model

- Material

- Mild Steel, Acrylic, Plastic components

- Product Type

- Demonstration Model

- Mould For

- Air Brake System Working

- Mould Size

- Approx. 60 cm x 30 cm x 25 cm

- Mould Material

- Mild Steel & Acrylic

- Design

- Detailed cutaway & functional layout

- Quality

- Laboratory/Instructional Grade

MODEL OF AIR BRAKE SYSTEM WORKING Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Western Union, Paypal, Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Western Europe, Africa, Central America, Eastern Europe, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About MODEL OF AIR BRAKE SYSTEM WORKING

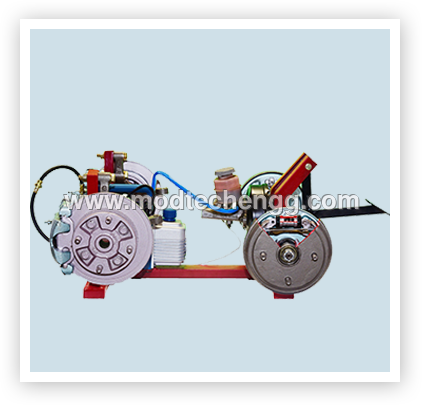

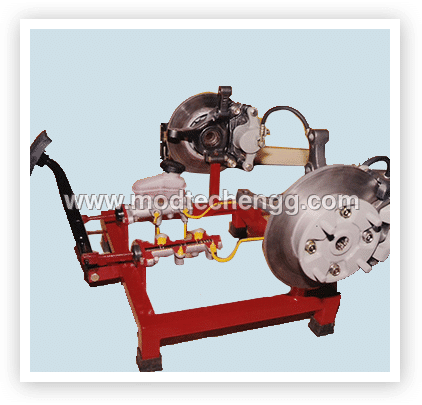

Model No. MT-K03

MODEL OF AIR BRAKE SYSTEM WORKING:

The model is made out of Original parts such as Air compressor, Unloader valve, foot valve, Booster, Wheel assembly, air tank, control valve etc The Brake system will be fitted with two front wheel assembly complete ( with out axle) and the drum will be suitably sectioned to show the working of the brake shoe. Other system will be mounted as it is and will be made to function ( foot brake, hand brake etc will be functional.)the entire system will be mounted on a sturdy iron frame. A F.H.P Single phase220/230 V AC motor will be coupled to the compressor for generation of the air, which is used for the operation of the model.

Comprehensive Air Brake System Demonstration

This model effectively illustrates the core components and working principle of air-operated braking as used in modern vehicles. Its detailed construction allows students to observe the interaction between the compressor, reservoir, valves, brake chamber, and actuator in real time, facilitating a deeper understanding of pneumatic brake mechanisms.

Built for Practical, Hands-on Learning

Engineered with portability and durability in mind, the model offers a robust mild steel and acrylic build. Its designed for repeated classroom use, ensuring both longevity and clear visual access for group instruction. The hand-operated controls simulate real-world usage without requiring any electrical power, making it universally accessible.

FAQs of MODEL OF AIR BRAKE SYSTEM WORKING:

Q: How does the MODEL OF AIR BRAKE SYSTEM WORKING operate?

A: This model functions manually by hand-actuating the brake pedal, which simulates air compression and distribution through its system. As you operate the pedal, air moves from the reservoir tank via the pipes and control valves, eventually activating the actuator in the brake chamber to mimic actual braking.Q: What components are included in the air brake system model?

A: The model includes a reservoir tank, compressor, brake pedal, piping, brake chamber, various control valves, and an actuator. All components are assembled on a powder-coated, rigid metallic frame for stability and clear visibility of each sections function.Q: Where is this model best utilized for training purposes?

A: This air brake system model is ideally suited for automobile engineering laboratories, polytechnic institutes, and technical training workshops where it serves as a practical aid for demonstrating air brake operation.Q: When should this air brake model be used during instruction?

A: The model is most effective during lessons on vehicle brake systems, pneumatic circuit analysis, or while introducing students to automotive safety mechanisms. It is particularly useful in hands-on demonstration sessions and laboratory experiments.Q: What is the benefit of using this air brake system model for educational purposes?

A: Using this model allows students to visually and physically understand the functions and interconnections within an air brake system, fostering a better grasp of pneumatic braking and safer design principles in automobiles.Q: How portable and durable is the air brake system model?

A: Weighing between 8 to 12 kg, the model is designed for easy mobility and robust enough for rigorous use. Its mild steel and acrylic construction ensures it withstands frequent handling, making it convenient for classroom demonstrations.Q: What materials and size are used in constructing the model?

A: The model is constructed primarily from mild steel, acrylic, and plastic, guaranteeing a laboratory-grade instructional tool. It measures approximately 60 cm x 30 cm x 25 cm and is mounted on a stable metallic frame with base support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cut Section Model of Brake System Category

CUT SECTION MODEL OF AIR BRAKE SYSTEM

Price 200000 INR

Minimum Order Quantity : 1 , , Unit

Stand Type : Stable Metal Base with Mounting

Mould Size : Standard Scaled Size (Compact Tabletop)

Mould For : Demonstration of Air Brake Systems

Design : Cutaway for Internal Mechanism Visualization

CUT SECTION MODEL OF MECHANICAL BRAKE SYSTEM

Price 20000 INR

Minimum Order Quantity : 1 , , Piece

Stand Type : Rigid Mounted Base

Mould Size : Standard Classroom Size

Mould For : Educational Display

Design : Sectional View Exposing Internal Mechanism

CUT SECTION MODEL OF DISC BRAKE SYSTEM

Price 200000 INR

Minimum Order Quantity : 1 Unit

Stand Type : Sturdy Base Stand

Mould Size : Approx. 350mm x 200mm x 120mm

Mould For : Disc Brake System

Design : Realistic, Crosssectional

CUT SECTION MODEL OF DISC BRAKE SYSTEM TWO WHELER

Price 200000 INR

Minimum Order Quantity : 1 Unit

Stand Type : Mounted on Acrylic/Metal Stand

Mould Size : Standard (Approx. 300x200x120 mm)

Mould For : Disc Brake System (Two Wheeler)

Design : Cut Section View with Detailed Internal Parts

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS