ELECTRONIC FUEL INJECTION SYSTEM OF DIESEL ENGINE

ELECTRONIC FUEL INJECTION SYSTEM OF DIESEL ENGINE Specification

- Features

- Sensor integration, real-time display, modular build, safe handling

- Surface Finish

- Powder Coated and Anodized

- Model No

- EFI-DE-2023

- Use

- Educational Demonstration and Engine Testing

- Assembly

- Preassembled, ready to use with minor setup

- Style

- Modern Industrial

- Power Type

- Electric Powered (220V/50Hz AC)

- Weight

- Approx. 24-28 kg

- Size

- Standard Compact Engine Bench

- Type

- Demonstration & Training Kit for Diesel Engines

- Material

- Mild Steel, Aluminum, and Engineering Plastics

- Dimensions

- Approx. 60 cm x 45 cm x 35 cm

- Shape

- Rectangular (module housing & components arrangement)

- Color

- Silver, Black, and Yellow

- Function

- Controls fuel injection timing and quantity electronically

- Age

- Adult (for technical education and professionals)

- Advantage

- Precise fuel delivery, improved engine efficiency, reduced emissions

- Control Unit

- Microcontroller-based ECU with user interface

- Documentation

- Comprehensive user and service manual included

- Input Supply

- Single-phase AC, 220V ±10%, 50 Hz

- Display

- Digital panel for monitoring system performance

- Mounting

- Bench-top with vibration isolators

- Injection Pressure

- Up to 1400 bar (adjustable)

- Compatible Engine Type

- 4-stroke Single Cylinder Diesel Engines

- Sensors Included

- Crankshaft position, fuel pressure, and temperature sensors

- Injector Type

- Solenoid controlled electronic injectors

- Safety Features

- Emergency stop, fuse protection, overcurrent cutoff

- Application

- Automobile, agricultural & research diesel engines

ELECTRONIC FUEL INJECTION SYSTEM OF DIESEL ENGINE Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Western Union, Paypal, Telegraphic Transfer (T/T)

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- North America, Eastern Europe, Africa, Central America, Middle East, South America, Asia, Australia

- Main Domestic Market

- All India

About ELECTRONIC FUEL INJECTION SYSTEM OF DIESEL ENGINE

INSTRUCTION BOARD FOR ELECTRONIC FUEL INJECTION SYSTEM OF DIESEL ENGINE.(CRDI)

The Instruction board adopts the real components of electronic fuel injection system( CRDI) to illustrate engine fuel system structure and working principle. The components are rigged onto colour circuit diagram. And made functional.

Features

Real and operatable engine fuel injection system with partial engine block is assembled onto a colour printed board to illustrating the structure and working process .

Coloured circuit diagram on the training Module printed on to 6mm organic glass base. Where in the students can compare the diagram and actual diagram.

Detection terminals for operator to detect various sensors, actuators, electrical signals for engine control unit, such as resistive, voltage, current , frequency and wave form signals are provided on to the printed circuit diagram.

The training module is fitted with diagnostic socket (DLC) for universal automobile decoder (Scan tool) to read fault codes, clear fault codes and read data stream.

Fault setting switch bank will be provided to induce faults in the training module to demonstrate the fault and to diagnose faults.

Set the line break, grounding short circuit, improper contact or open circuit faults can be induced, user can adjust the number and type of faults.

Good working condition Parts will be provided with fuel tank. The instruction board has to be connected to 220V AC socket Which changes to 12V DC internally, so that the board works without battery.

The training module is fabricated using steel pipe frame with spray painted for good looks and the entire setup is provided with caster wheels with brakes for easy movement of the same.

Advanced Electronic Control for Diesel Engines

Harnessing a microcontroller-based ECU and state-of-the-art sensors, this system enables real-time electronic fuel delivery management for diesel engines. Adjusting injection pressure up to 1400 bar is straightforward, allowing fine-tuned control of engine performance for testing, learning, or research. The modular, compact build integrates seamlessly with single-cylinder diesel test benches, further emphasizing its adaptability.

Comprehensive Safety and Ease of Use

Designed with both safety and user convenience in mind, the EFI-DE-2023 incorporates emergency stop, fuse protection, and overcurrent cutoff mechanisms. The digital interface provides immediate feedback, while its robust housing absorbs vibrations during operation. It is shipped preassembled, allowing quick and easy integration into labs and testing setups with minimal effort.

Versatile Educational and Research Application

This demonstration kit is ideal for technical education, hands-on engineering training, and in-depth engine research. Its precise, modular design makes it a valuable asset for analysis of modern diesel fuel injection principles. Comprehensive user and service documentation supports educators and professionals alike, ensuring effective knowledge transfer and system maintenance.

FAQs of ELECTRONIC FUEL INJECTION SYSTEM OF DIESEL ENGINE:

Q: How is the EFI-DE-2023 system installed and set up for operation?

A: The EFI-DE-2023 system is provided preassembled, streamlining installation. Simply position it on a stable bench-top surface with vibration isolators, connect the compatible 4-stroke single-cylinder diesel engine, and supply 220V 10% single-phase AC power. Basic setup steps are covered in the comprehensive manual.Q: What types of diesel engines are compatible with this electronic fuel injection system?

A: The system is specifically designed for 4-stroke single-cylinder diesel engines, making it suitable for a wide array of educational, automotive, agricultural, and research engine test platforms.Q: When should you use the emergency stop or safety features?

A: Safety features like the emergency stop, fuse protection, and overcurrent cutoff should be used during abnormal system behavior, suspected electrical faults, or whenever immediate cessation of operation is required to prevent equipment or personal injury.Q: Where can performance data and system status be monitored?

A: All critical system parameters, including injection timing, pressure, and sensor readings, are displayed in real-time on the integrated digital panel, facilitating immediate monitoring and adjustment as needed.Q: What is the process for adjusting the fuel injection pressure?

A: Injection pressure is fully adjustable up to 1400 bar. The procedure involves using the user interface on the ECU, as guided in the supplied manual, to set the desired value appropriate for your engine and testing objectives.Q: How does the system enhance fuel delivery and reduce emissions?

A: By electronically controlling the injection timing and quantity with high precision via the microcontroller and sensors, the system ensures optimal combustion. This results in improved fuel efficiency and reduced harmful emissions compared to conventional mechanical fuel injection systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Instruction Boards/Training Platforms Category

REVERSE CAMERA AND PARKING ASSIST SYSTEM

Price 2000 INR

Minimum Order Quantity : 1 , , Unit

Features : IR LED Night Vision, Grid Marking, Water Resistant, Shock Proof, Wide Angle Lens

Shape : Rectangular

Dimensions : 85mm x 30mm x 30mm (Camera Unit)

Model No : RCPA102

INSTRUCTION BOARD FOR ELECTRONIC FUEL INJECTION SYSTEM

Price 200000 INR

Minimum Order Quantity : 1 Unit

Features : Detailed EFI System Circuit, Component Labeling, EasytoRead Graphics

Shape : Rectangular

Dimensions : 900 mm x 600 mm x 100 mm

Model No : EFIIB2024

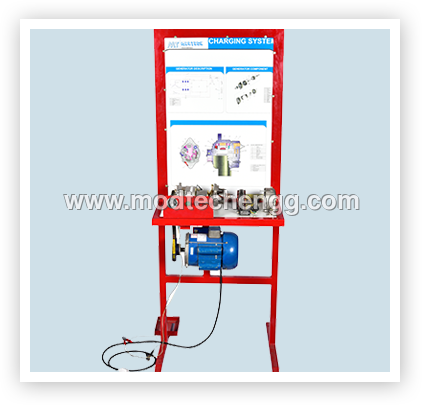

INSTRUCTION BOARD FOR CHARGING SYSTEM

Price 2000 INR

Minimum Order Quantity : 1 Unit

Features : Weatherproof, Easy to Mount, Fadeproof

Shape : Rectangular

Dimensions : 30 x 45 cm

Model No : CSIB11

INSTRUCTION BOARD FOR STARTING SYSTEM

Price 2000 INR

Minimum Order Quantity : 1 Unit

Features : Labeled components, clear print, easy wall mounting, educational purpose

Shape : Rectangular

Dimensions : 600 mm x 800 mm

Model No : STISB01

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free